4 Best Wood Laser Engravers and Cutters of 2023

When choosing a laser engraver and cutter for wood, it's important to prioritize the quality of the final output over the mere ability of the machine to carve and cut wood. While some machines can carve or cut wood quickly, they often leave unsightly burn marks, charred edges, and fail to capture intricate image detail. This machine is not suitable for wood carving or cutting.

To avoid suboptimal results like these, it's important to focus on the quality of your wood laser engraver and cutter, not just its features. High-quality wood laser engravers and cutters produce precise, detailed, and visually appealing engravings with clean, smooth edges and no burn marks.

Finding the best wood laser engraver can be a challenging task, but by following this guide, you'll learn what to look for and what to consider when choosing a wood laser engraver and cutter.

Types of Wood Laser Engravers and Cutters

A laser engraver is the ideal tool for achieving precise and intricate designs on wood. Unlike traditional engraving methods, laser engraving utilizes a powerful laser beam to mark designs on the surface of the wood. When the laser beam comes into contact with the wood surface, the temperature of the wood surface rises rapidly. Thanks to powerful energies, material is removed from the surface, resulting in intricate and detailed designs that are both visually and tactilely appealing.

In wood laser engraving, material is slightly removed from the surface and you can see and feel the deep 3D cuts.

In wood laser cutting, a laser beam is passed through the wood, cutting it into precise pieces. This is a very effective way to create complex shapes and designs with clean and precise edges.

Overall, laser engraving and cutting are the best methods for custom woodworking because of their high precision, accuracy, and efficiency. They are ideal for creating custom designs, intricate patterns and unique shapes that are difficult to achieve with traditional methods.

There are many types of wood laser engraving and cutting machines on the market, such as CO2 laser engraving machines, diode laser engraving machines, fiber laser engraving machines, infrared laser engraving machines, etc. However, the best machines for wood engraving and cutting are CO2 and diode laser machines.

CO2 laser cutters are very powerful and take less time to engrave or cut wood, but are expensive. Diode lasers take more time, but a powerful 20W diode laser can also do the job quickly.

Atomstack S20 Pro 20W Quad-Laser Engraver Cutter

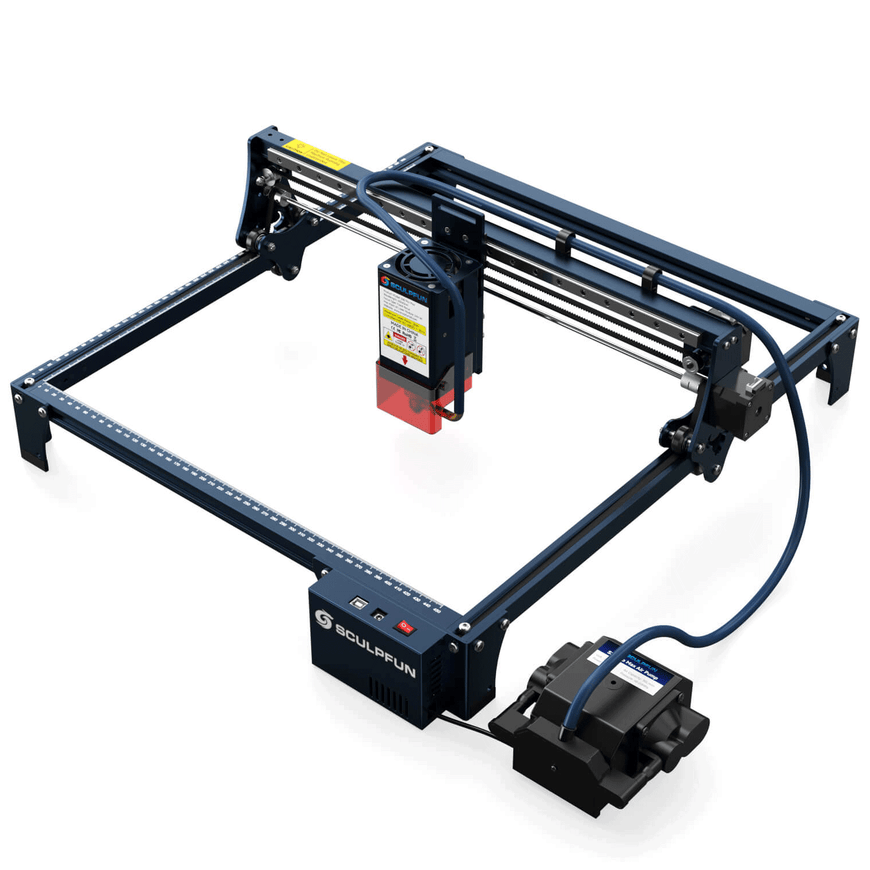

Sculpfun S30 Pro Max 20W Laser Engraver Cutter

TwoTrees TS2 20W Laser Engraver Cutter

Longer RAY5 20W Laser Engraver Cutter

The results from both the wood laser engraving machine and the wood laser cutting machine are excellent. Their focused laser beam produces a small spot size, allowing even the tiniest details to be captured. This intricate detail and finish cannot be achieved with any other wood carving or cutting process.

What is a good wood laser engraver?

There are certain things and factors you should keep in mind when purchasing a wood laser engraver. Certain features, features, and capabilities of laser engravers make them ideal for engraving wood.

1. Fewer burn marks

A laser engraver emits an extremely powerful laser beam that raises the temperature of the surface of the material on which the laser beam falls. The temperature rises rapidly and evaporates the material. You may like a very powerful laser, but in the case of wood, the power shouldn't be too strong as it will leave burn marks on the object. Wood is very fragile, which is why the optical power of wood laser engravers and cutters is very important.

Typically, for hobby grade wood laser engraving machines, diode lasers range from 5W to 40W and CO2 lasers range from 40W to 60W. Higher power settings should be paired with higher engraving or cutting speeds to reduce the dwell time of the laser on the wood, thereby avoiding burn marks.

In addition, to remove burn marks on the back of the object, a suitable laser bed must be used. Honeycomb panels are an ideal bed for wood laser engraving or cutting because it allows heat to dissipate quickly.

2. Air assist

Gas assist is an essential accessory for wood laser engraving. If you want to see perfect results, make sure your wood laser engraver has that. Not only does it blow away the smoke, but it also prevents discoloration of the woodwork. The air assist throws a powerful airflow and takes away the fumes created while engraving. Second, it also blows debris.

3. Working area and height

The working area of a wood laser engraving machine is an important factor to consider when choosing the best machine for your needs. It determines the size of objects you can sculpt and the types of projects you can take on. For DIY projects and small businesses, a working area of at least 400 x 300mm is suitable. This size is large enough to engrave small to medium objects and will meet the needs of most hobbyists and small businesses.

The height of the wood laser engraver is also a key factor. While this aspect may be overlooked by some beginners and hobbyists, it is essential for accommodating various object sizes and types of sculpting projects. By choosing a laser engraver with an exceptional height, you can easily engrave more objects or thicker materials. Additionally, the greater height provides the flexibility to use the swivel attachment to engrave cylindrical objects such as wine bottles, mugs, or other round surfaces.

Additionally, a wood laser engraving machine with an adjustable height option is ideal. It allows you to vary the height according to the thickness of the material being engraved, giving you more precise control over the engraving process.

4. Fine laser spot

For wood laser engraving, the laser spot should be as small as possible. The smaller the spot size, the more details can be considered when engraving. The laser spot should be smaller than 0.1 x 0.1mm. This value is just for your consideration, but you can easily get a smaller laser spot.

5. High precision

The accuracy of a wood laser engraver should be very good. The software guides and moves the laser head to different positions. The engraving result will be perfect, if the precision is very good, the error will be minimal. In some laser engravers, the motion is accurate to 0.004 inches (0.1 mm). Another important factor related to accuracy is repeat position accuracy. It ensures minimal error when the laser head is moved to the previous position. Some machines have obvious repeat position errors, so you need to pay attention to this specification as well. Suitable positioning accuracy for fine engraving is 0.007-0.010 inches (0.2-0.3mm).